Webbing materials are an essential component in various industries, from automotive safety to outdoor equipment and fashion accessories. Among common types of webbing are PVC coated polyester webbing, polyester seat belt webbing, and nylon seat belt webbing. Each of these materials offers unique properties that make them suitable for specific applications.

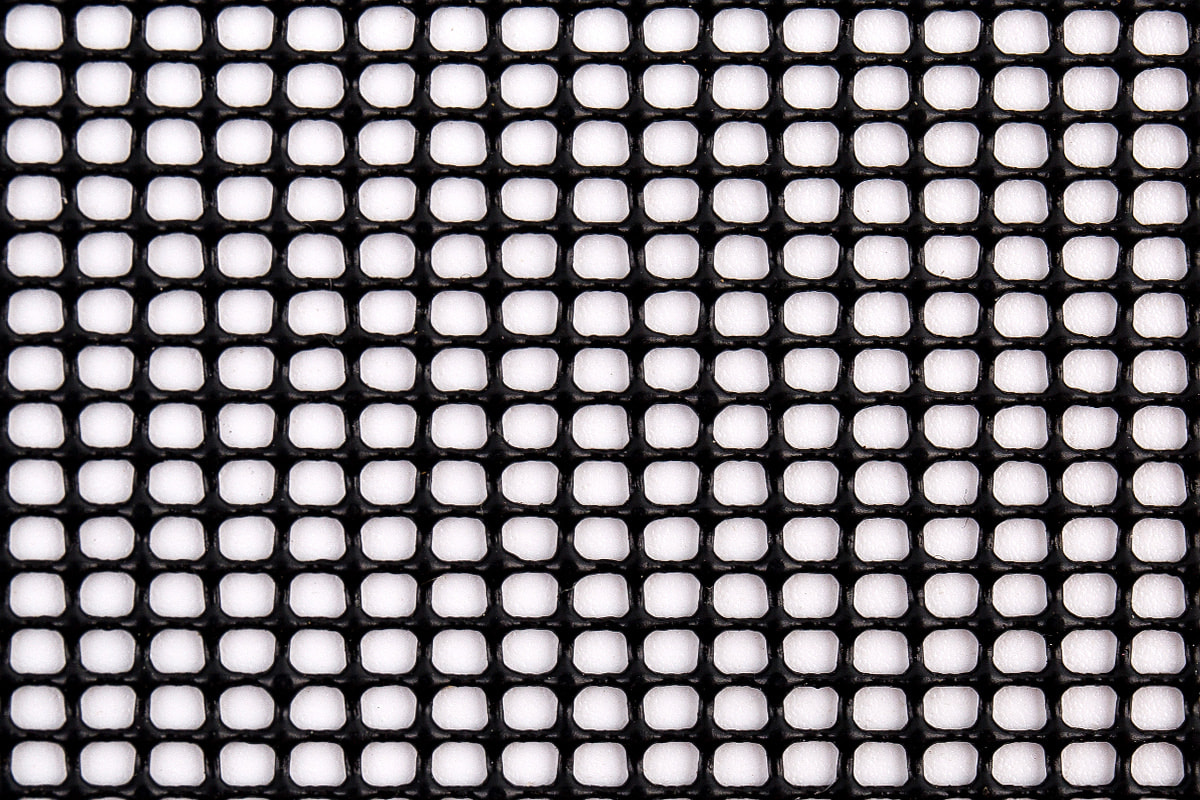

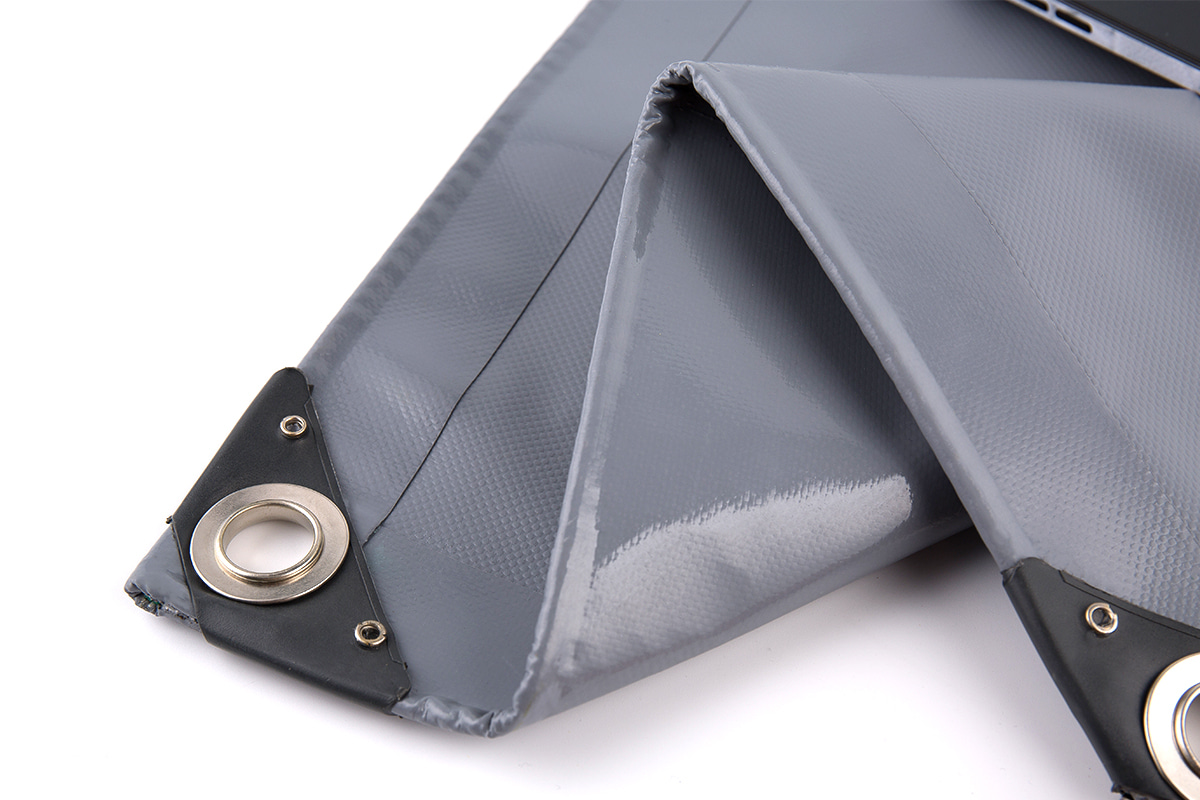

PVC coated polyester webbing is a versatile material that combines the strength of polyester with the protective qualities of PVC coating. This type of webbing is known for its durability, resistance to water, and ease of cleaning. The PVC coating provides an additional layer of protection against abrasion and UV damage, making it ideal for outdoor use. The material is also lightweight and flexible, allowing it to be used in a wide range of applications.

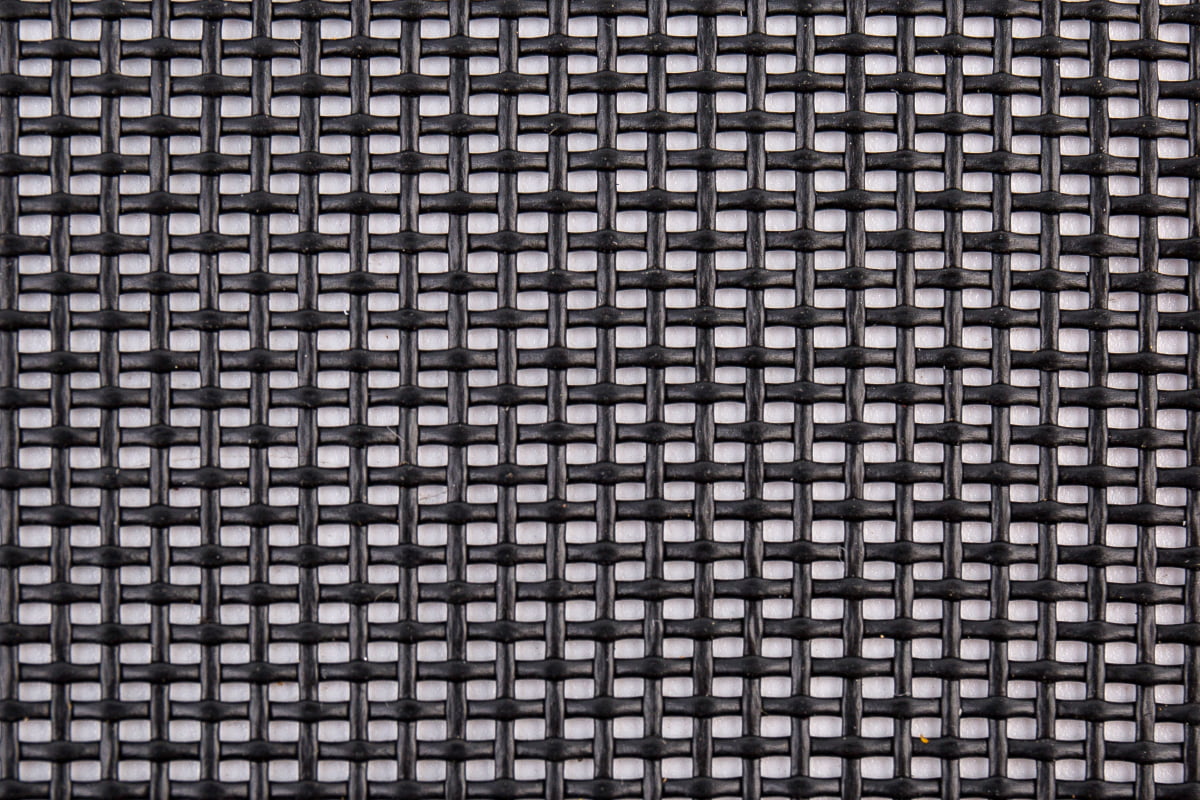

Polyester seat belt webbing is a staple in the automotive industry due to its high tensile strength and resistance to wear and tear. This type of webbing is designed to withstand the forces exerted during a vehicle collision, providing a secure and reliable means of restraint. Polyester webbing is also resistant to various environmental factors, such as sunlight, heat, and moisture, ensuring its longevity and performance over time. The material is easy to work with, allowing for seamless integration into seat belt systems.

Nylon seat belt webbing is another popular choice for automotive safety due to its high strength-to-weight ratio. Nylon webbing is known for its outstanding elasticity, allowing it to stretch and absorb energy during an impact, thereby reducing the force transmitted to the occupant. This material is also resistant to chemicals, making it suitable for use in environments where exposure to various substances is possible. Nylon webbing is often used in combination with polyester to create a hybrid seat belt system that offers both materials.

While all three types of webbing materials have their strengths, they also have specific applications where they excel. PVC coated polyester webbing is ideal for outdoor and industrial applications where protection from the elements is necessary. Polyester seat belt webbing, with its high tensile strength, is suited for automotive safety applications. Nylon seat belt webbing, on the other hand, is preferred for its elasticity and resistance to chemicals, making it suitable for both automotive and industrial uses.

The environmental impact of these materials is also an important factor to consider. PVC coated polyester webbing, while durable, may raise concerns due to the potential for PVC to release harmful chemicals during its lifecycle. Polyester and nylon, being synthetic materials, also have their environmental drawbacks, such as the energy-intensive manufacturing process and the difficulty of recycling. However, advancements in recycling technologies and the development of more sustainable production methods are helping to mitigate these concerns.

The textile industry is continuously evolving, with new innovations in webbing materials emerging regularly. For instance, the development of high-strength, lightweight composite materials is pushing the boundaries of what is possible in terms of strength and durability. Additionally, advancements in coating technologies are improving the protective qualities of PVC coated polyester webbing, making it even more versatile for various applications.

The PVC coated polyester webbing, polyester seat belt webbing, and nylon seat belt webbing each offer unique properties that make them suitable for a range of applications. From the protective qualities of PVC coatings to the strength and durability of polyester and nylon, these materials play a crucial role in ensuring safety, durability, and performance in various industries. As technology advances and environmental concerns become more prominent, the development of innovative and sustainable webbing materials will continue to be a priority, further enhancing the capabilities and applications of these essential textiles.

en

en Español

Español