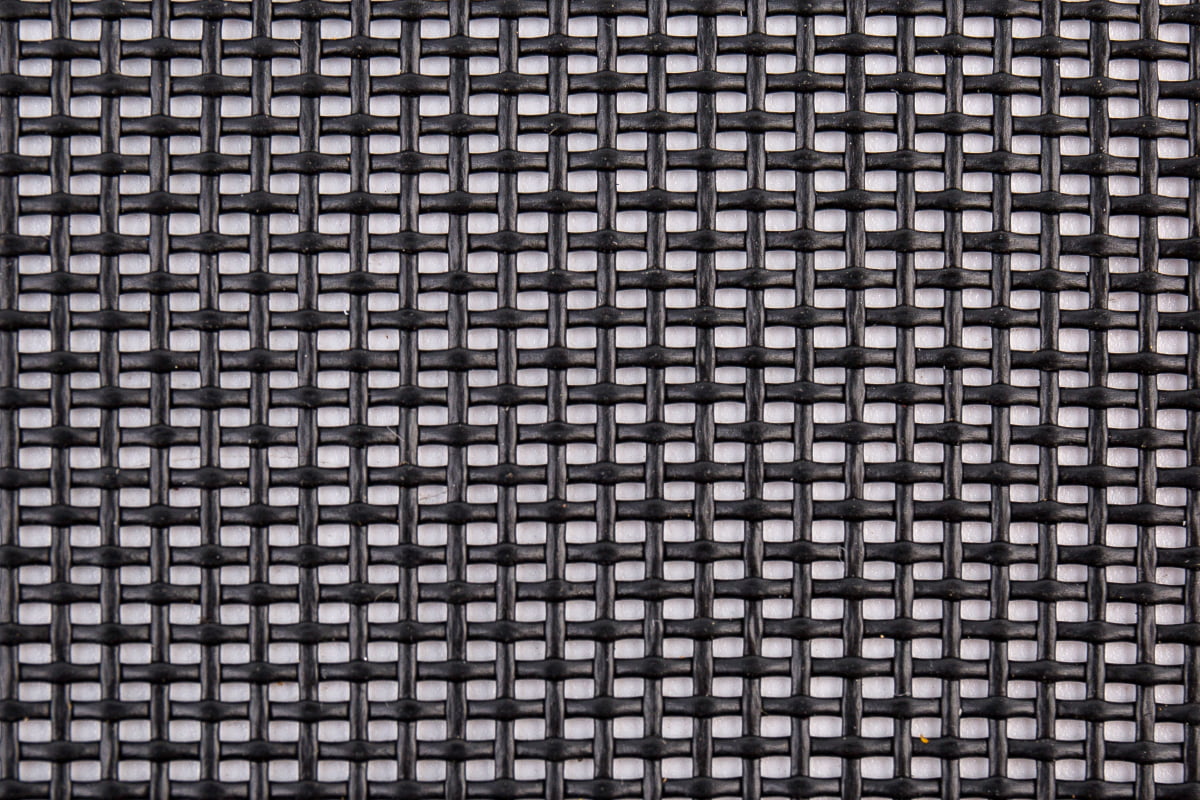

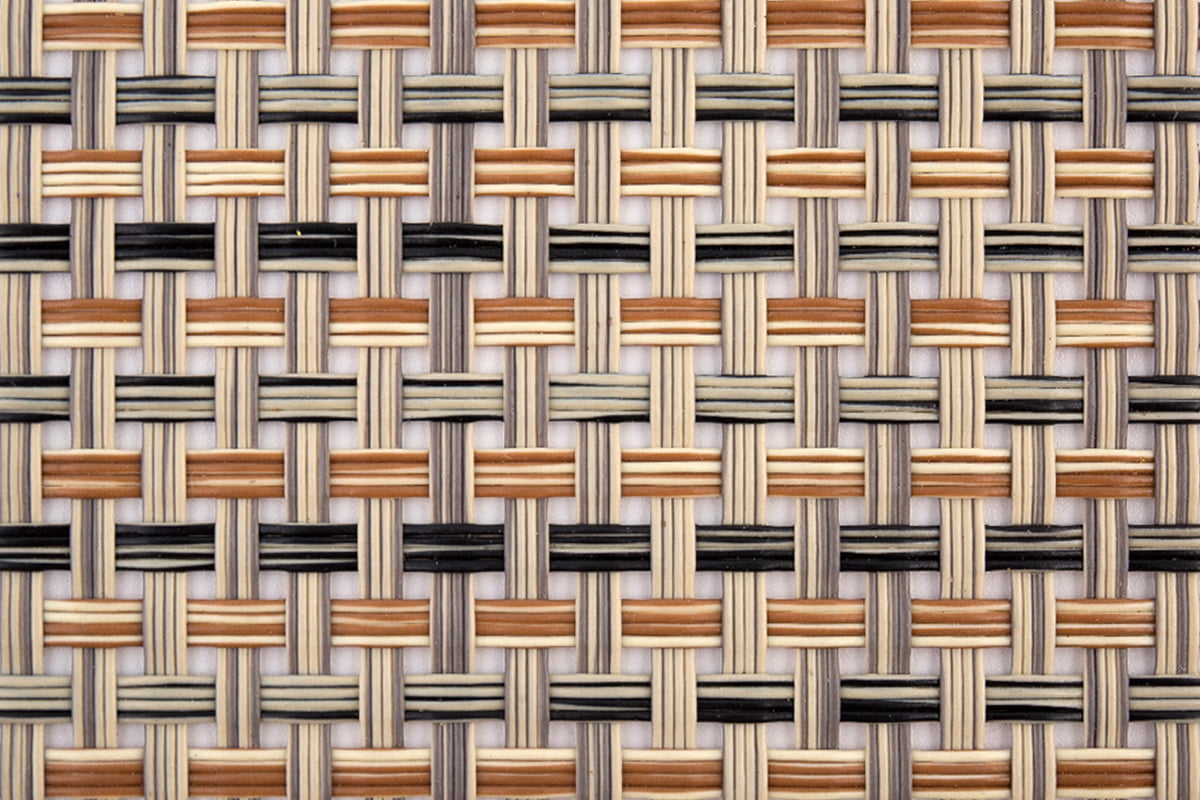

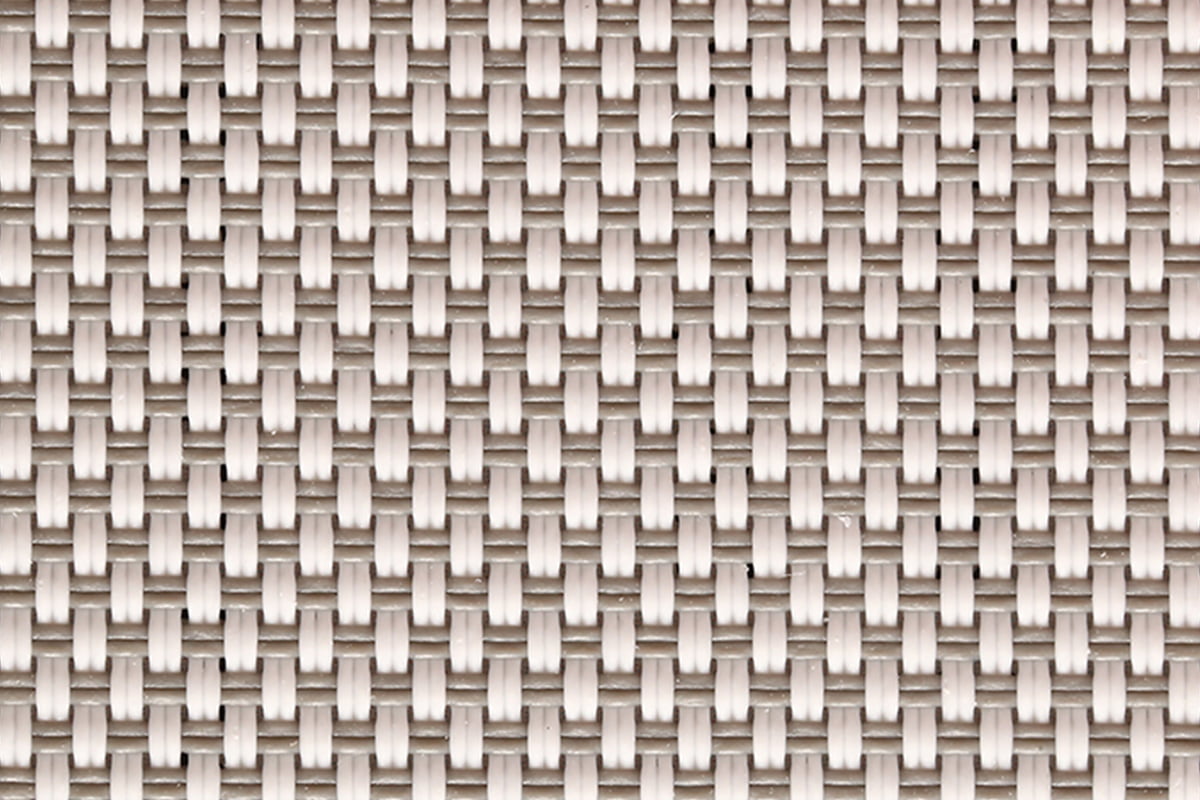

High quality wholesale eco friendly mesh fabric for sale

With the increasing awareness of global environmental protection, the textile industry, as a traditional field with high energy consumption and high emissions, is facing the pressure of transformation. Eco friendly mesh fabric as a clear stream in the textile industry, the energy-saving and emission reduction measures taken in the production process not only highlight the enterprise's sense of responsibility for environmental protection, but also set a model for the sustainable development of the industry.

Wide application of low energy consumption equipment

The production of eco friendly mesh fabric pays attention to energy saving and emission reduction from the source. In key links such as spinning, weaving, dyeing and post-processing, enterprises introduce advanced low-energy equipment. For example, the use of energy-efficient spinning machines to significantly reduce energy consumption by optimizing heating systems and melting processes; in the process of eco friendly mesh fabric weaving, the intelligent control system can precisely adjust the speed, tension and density of the loom, reduce ineffective energy consumption and improve production efficiency. In addition, the low-energy dyeing machine reduces the waste of heat energy and water resources by precisely controlling the amount and temperature of the dye, while ensuring the uniformity and stability of the dyeing effect.

Innovative application of water recycling system

Water resource is an indispensable resource in textile production, but the traditional printing and dyeing process is often accompanied by a large amount of wastewater discharge. In the production process of eco friendly mesh fabric, enterprises actively adopt advanced water recycling systems to achieve the reduction, harmlessness and resource of wastewater. By means of multistage filtration, biochemical treatment and membrane technology, the system can effectively remove the pollutants in the wastewater, so that the treated water quality can reach the reuse standard. In this way, the wastewater that originally needed to be discharged is reintroduced into the production process for cleaning, cooling and other links, greatly reducing the use of fresh water and reducing the environmental burden.

The use of clean energy

In order to further reduce carbon emissions, eco friendly mesh fabric manufacturers are also actively using clean energy. For example, solar photovoltaic panels are installed in the factory to convert solar energy into electricity for production use; introducing biomass fuel or geothermal energy into the steam supply system to replace traditional fossil fuels. The use of these clean energy sources not only reduces the production cost of eco friendly mesh fabric, but also significantly reduces greenhouse gas emissions and injects new impetus into the green development of enterprises.

Process innovation and green supply chain management

In addition to the upgrading of hardware facilities, the production of eco friendly mesh fabric also focuses on process innovation and green supply chain management. Reduce chemical usage and waste generation by optimizing production processes; at the same time, strengthen cooperation with raw material suppliers, promote the green transformation of the upstream industrial chain, and ensure the environmental protection and sustainability of the source of eco friendly mesh fabric raw materials.

In summary, the energy-saving and emission reduction measures taken in the production process of eco friendly mesh fabric are multi-faceted and comprehensive. These measures not only help reduce production costs, improve product quality and competitiveness, but more importantly, make positive contributions to environmental protection and sustainable development. In the future, with the progress of science and technology and the deepening of environmental awareness, we have reason to believe that the production of eco friendly mesh fabric will be more green, efficient and sustainable.

en

en Español

Español