Safety is paramount when it comes to driving, and one of the critical components ensuring our safety on the road is the seat belt. Specifically, auto seat belt webbing and automotive seat belt webbing play a crucial role in safeguarding passengers during a collision. Evaluating the safety of these materials is essential to ensuring they perform effectively under stress.

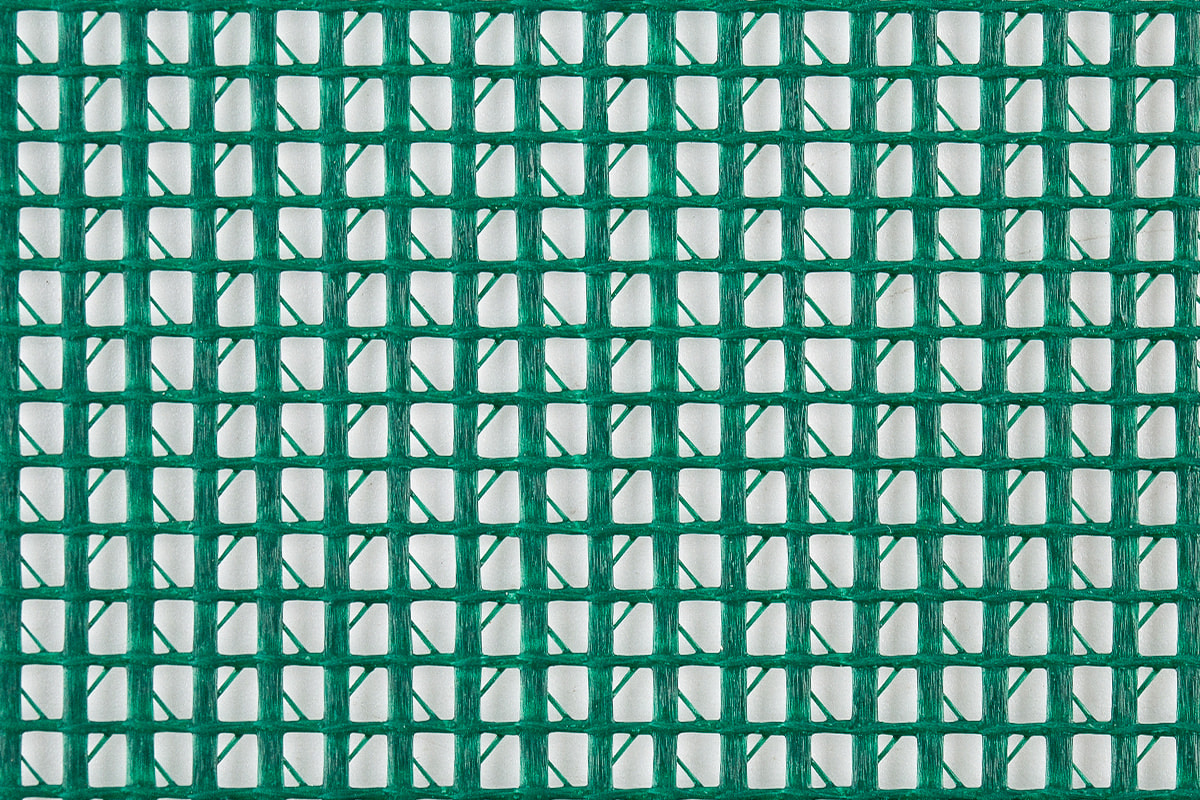

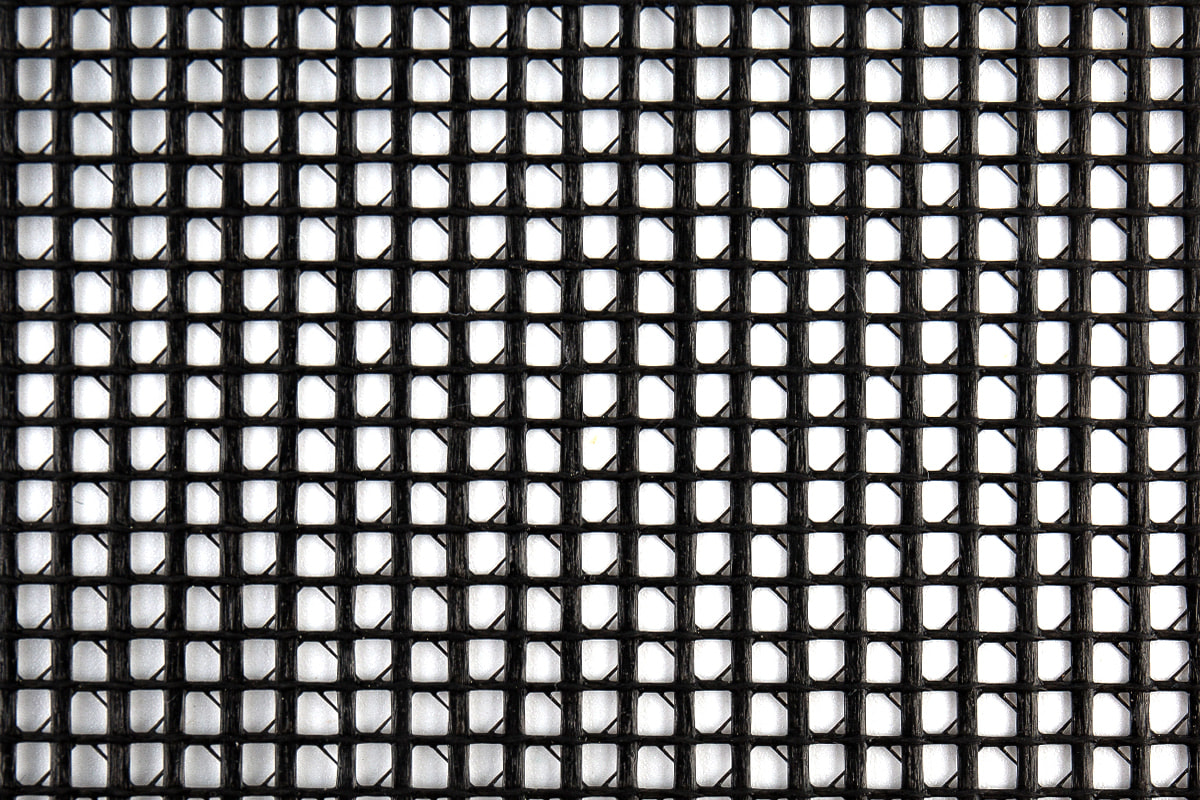

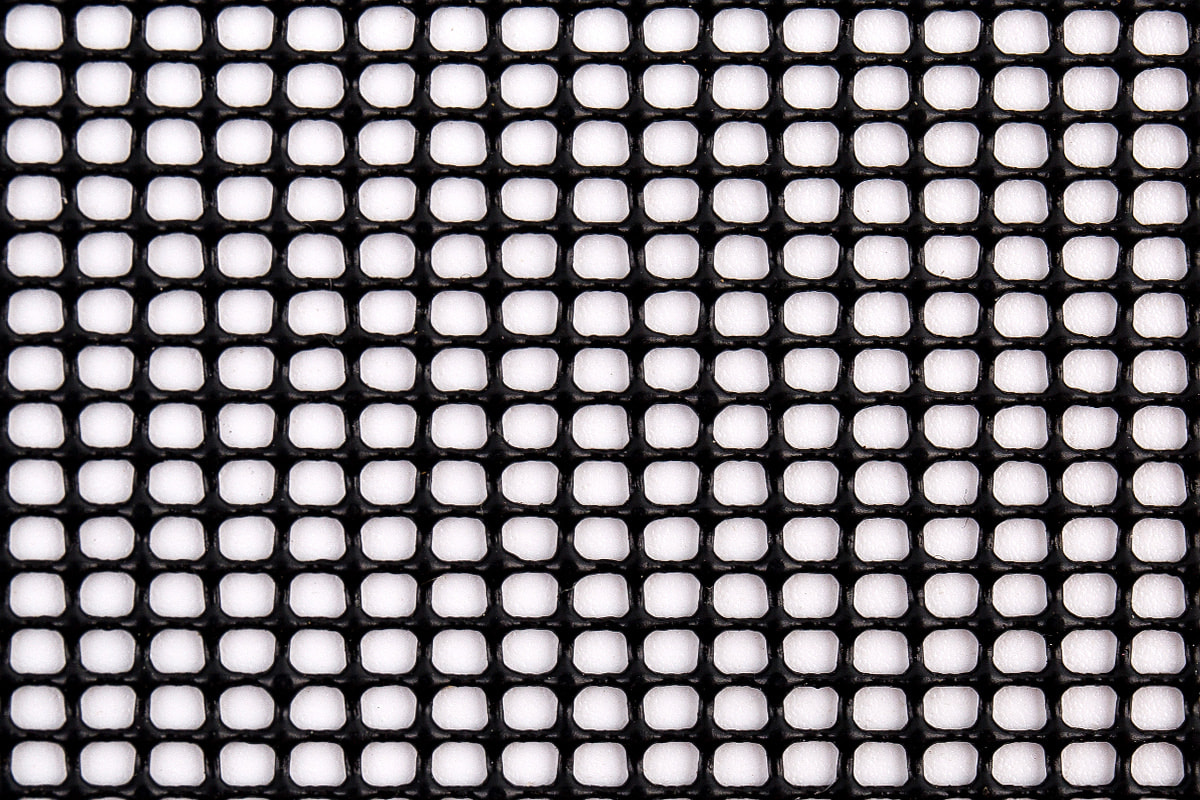

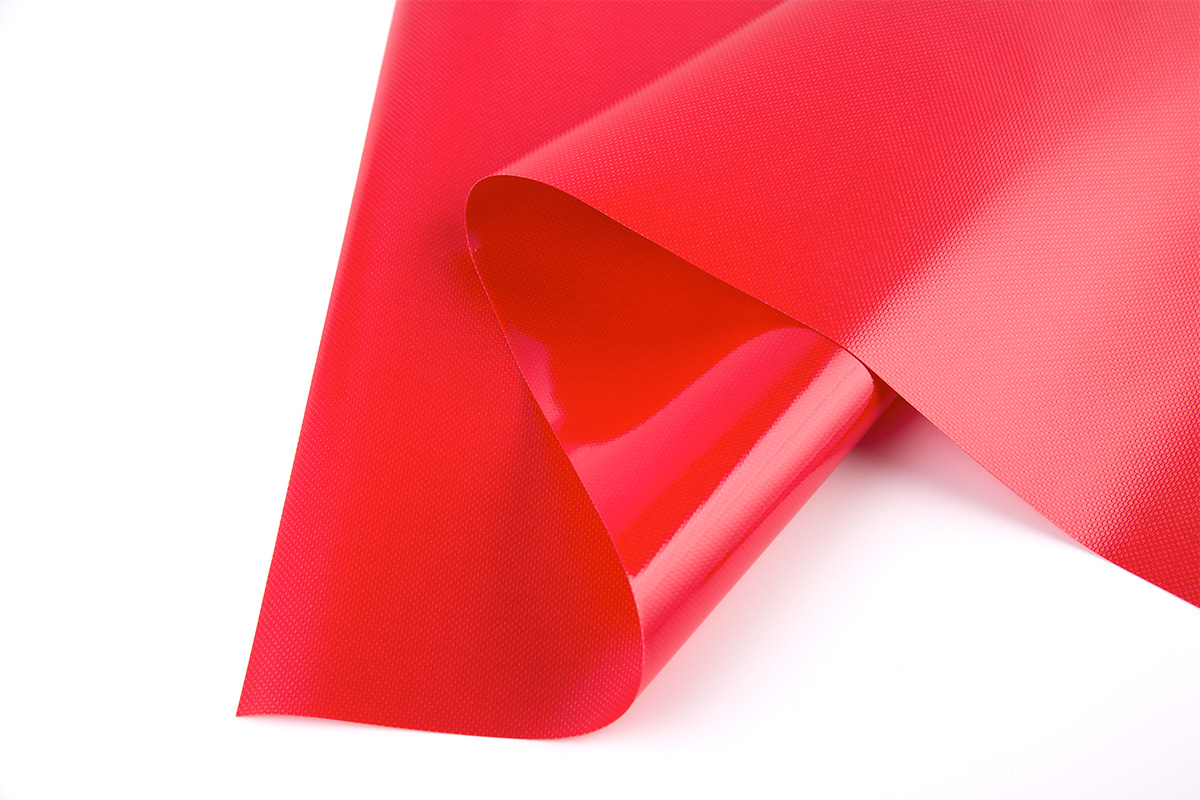

Auto seat belt webbing refers to the woven fabric that makes up the seat belt. It is designed to withstand significant forces during a crash, preventing passengers from being thrown forward. The webbing must be durable, flexible, and resistant to wear and tear. The materials used in the production of automotive seat belt webbing are typically polyester or nylon, known for their high tensile strength and durability.

One of the primary factors in evaluating the safety of auto seat belt webbing is the strength and durability of the material. Car seat belt material must be able to endure the force exerted during a collision without tearing or stretching excessively. Manufacturers conduct rigorous testing to ensure that the webbing can handle the impact forces encountered in crashes. These tests often involve pulling the webbing with a significant amount of force to ensure it does not fail under stress.

The webbing must also resist abrasion, as constant friction against metal components and clothing can wear it down over time. Abrasion resistance testing involves repeatedly rubbing the webbing against rough surfaces to simulate long-term use. High-quality automotive seat belt webbing should show minimal signs of wear after extensive testing, indicating it will remain effective over the lifespan of the vehicle.

Exposure to sunlight can degrade many materials, and auto seat belt webbing is no exception. UV radiation can weaken the fibers, reducing the webbing's overall strength. To combat this, manufacturers often treat car seat belt material with UV inhibitors to protect it from sun damage. Evaluating the UV resistance of the webbing is crucial, especially for vehicles frequently exposed to sunlight. This testing ensures the seat belts will not become brittle or lose strength over time.

Automotive environments expose seat belt webbing to various chemicals, including cleaners, spills, and environmental pollutants. High-quality automotive seat belt webbing must resist these chemicals to maintain its integrity. Testing for chemical resistance involves exposing the webbing to common automotive chemicals and observing any changes in strength or flexibility. Effective car seat belt material should show no significant deterioration when exposed to such substances.

Temperature fluctuations can also impact the performance of auto seat belt webbing. heat can cause some materials to soften, while cold can make them brittle. Manufacturers test the webbing's performance across a wide temperature range to ensure it remains reliable in all conditions. Automotive seat belt webbing must retain its strength and flexibility whether in the scorching heat of summer or the freezing cold of winter.

Another critical aspect of evaluating car seat belt material is ensuring it complies with safety standards set by regulatory bodies. In the United States, the National Highway Traffic Safety Administration (NHTSA) sets stringent standards for seat belt performance. These standards include criteria for webbing strength, elongation, and durability. Similar standards exist in other countries, and compliance with these regulations is non-negotiable for manufacturers. When evaluating auto seat belt webbing, checking for certification and compliance with these standards is essential.

Laboratory tests are crucial, but real-world testing and crash simulations provide valuable insights into the performance of automotive seat belt webbing. Manufacturers often use crash test dummies equipped with sensors to simulate various collision scenarios. These tests help assess how well the seat belt webbing restrains passengers during different types of crashes. Data from these simulations can reveal potential weaknesses and areas for improvement in the webbing design.

Once auto seat belt webbing is installed in a vehicle, regular inspections are necessary to ensure ongoing safety. Car owners should routinely check their seat belts for signs of wear, fraying, or damage. If any issues are detected, the seat belts should be replaced immediately. Regular maintenance, such as cleaning the webbing with mild soap and water, can also extend its lifespan and ensure it remains effective.

en

en Español

Español