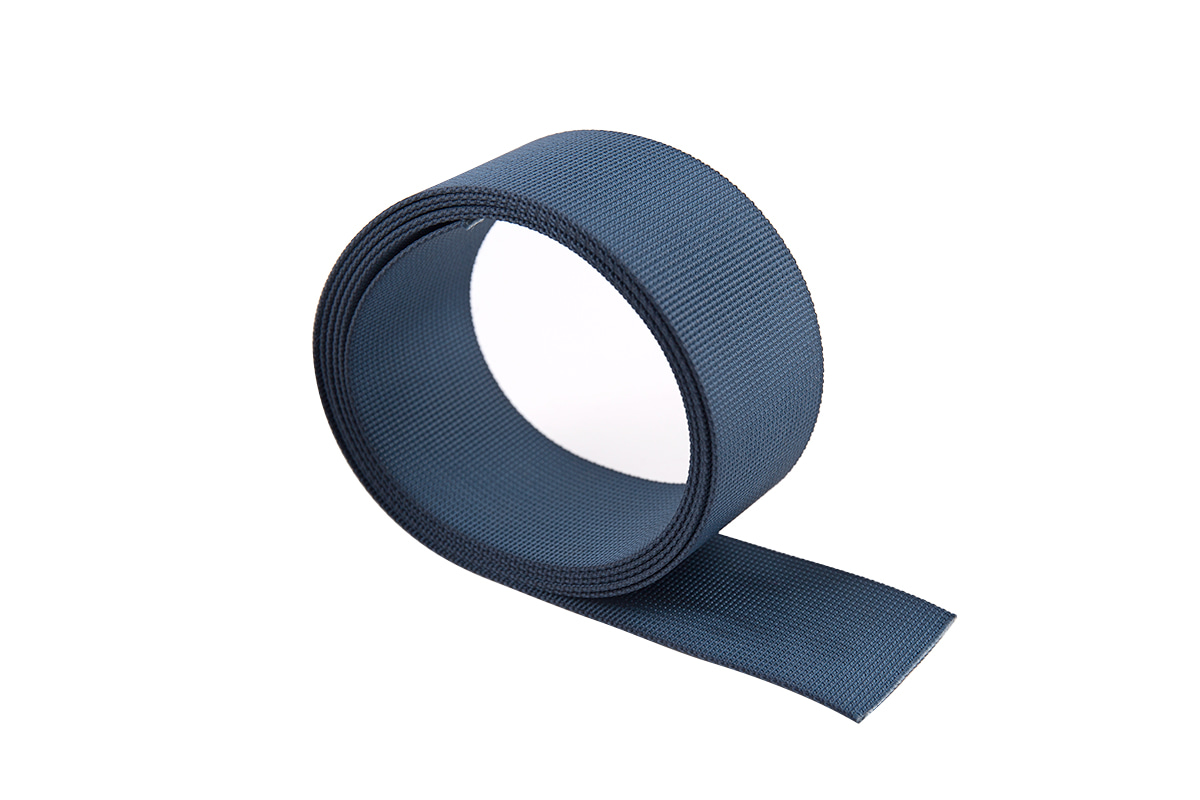

Seat belt webbing is typically made from high-strength fibers, such as polyester or nylon, which offer outstanding tensile strength and resistance to wear and tear. The choice of material is crucial because the webbing must withstand the immense forces exerted during a collision. Nylon webbing is particularly favored for its strength, elasticity, and durability, making it an ideal material for seat belt webbing.

The safety standards for seat belt webbing are rigorous and detailed, ensuring that every piece of webbing used in vehicles can effectively restrain passengers. These standards are set by various national and international organizations, including the Federal Motor Vehicle Safety Standards (FMVSS) in the United States and the European Economic Community (EEC) regulations in Europe. Key aspects of these standards include:

1. Tensile Strength: Seat belt webbing must have a relatively small tensile strength to ensure it can withstand the forces of a crash. This is typically measured in Newtons (N) and varies depending on the vehicle type.

2. Abrasion Resistance: To ensure longevity, seat belt webbing must resist wear and tear from regular use. Tests simulate repeated use over time to assess the webbing's durability.

3. UV Resistance: Nylon webbing and other materials used in seat belt webbing must be resistant to UV light to prevent degradation from sun exposure, which can weaken the fabric.

4. Flame Resistance: Seat belt webbing must meet specific flame retardancy standards to ensure it does not ignite easily, providing additional safety in the event of a fire.

The Manufacturing Process of Seat Belt Webbing

The manufacturing of seat belt webbing involves several steps, each critical to ensuring the final product meets safety standards. Here is an overview of the process:

1. Material Selection: The process begins with selecting high-quality fibers. Nylon webbing is often chosen due to its outstanding performance characteristics. The fibers are sourced from reputable suppliers to ensure consistency and quality.

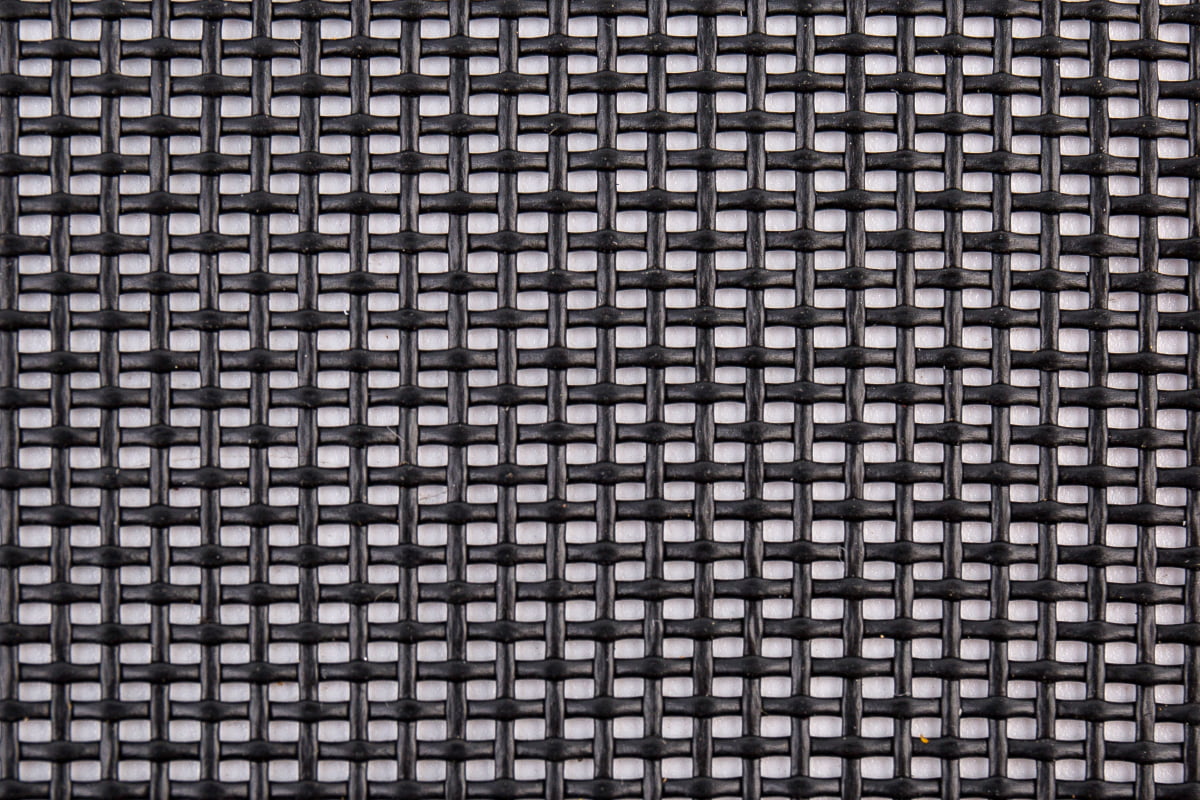

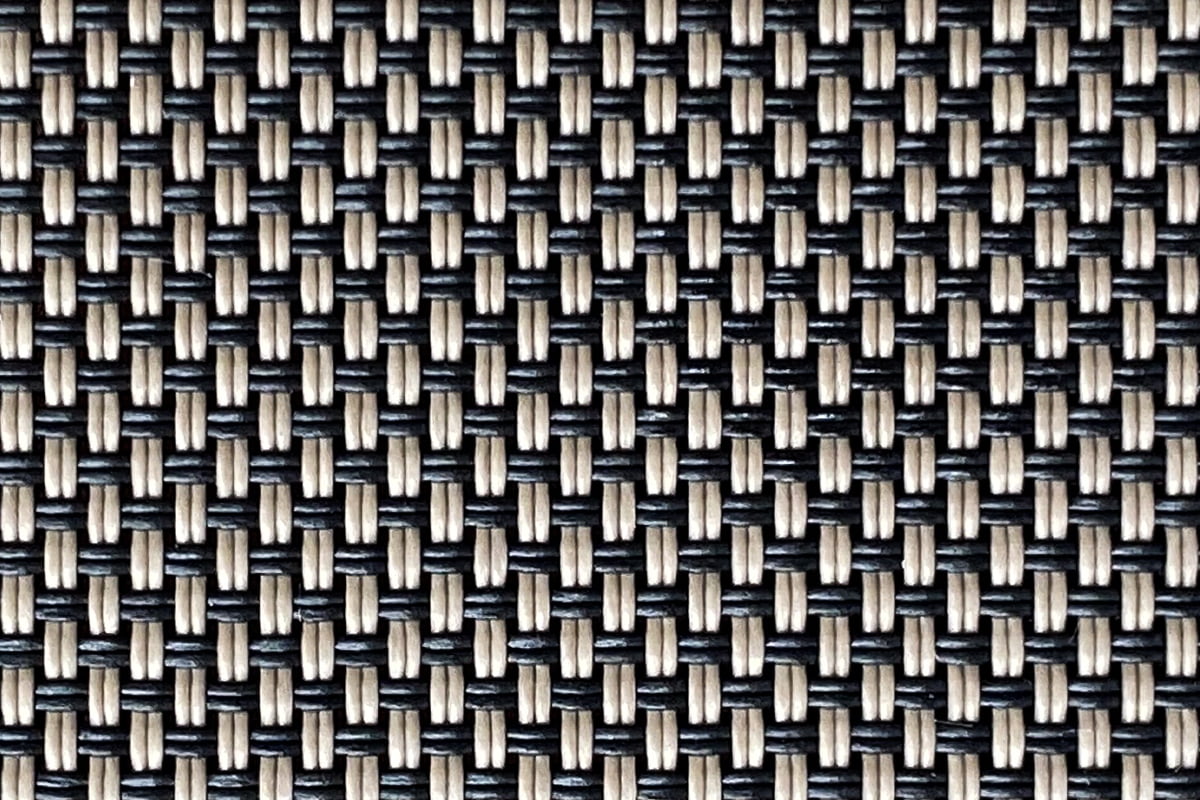

2. Weaving: The fibers are woven into webbing using specialized looms. The weaving process is tightly controlled to ensure the webbing has the required strength and flexibility. Nylon straps are created with precise patterns that improve their durability and performance.

3. Dyeing and Finishing: The woven webbing is then dyed to the desired color and treated with finishes that enhance properties such as UV resistance and abrasion resistance. These treatments are essential for maintaining the webbing's performance over time.

4. Quality Control Testing: Each batch of seat belt webbing undergoes rigorous testing to ensure it meets all safety standards. Tests include tensile strength testing, abrasion resistance testing, and UV exposure testing. Any batch that does not meet the standards is rejected.

5. Cutting and Assembly: Once the nylon webbing passes quality control, it is cut to the required lengths and assembled into seat belts. This step includes stitching, adding hardware such as buckles, and conducting final inspections.

Nylon webbing is often preferred in the manufacturing of seat belt webbing due to its unique properties. Nylon straps are known for their high tensile strength, which is crucial for withstanding the forces in a collision. Additionally, nylon webbing has outstanding elasticity, allowing it to absorb impact energy and reduce the risk of injury. Its durability and resistance to environmental factors such as UV light and abrasion make it a reliable choice for long-term use in vehicles.

The safety standards associated with seat belt webbing and its manufacturing process are designed to ensure high level of protection for vehicle occupants. The use of high-quality materials, such as nylon webbing, and rigorous testing protocols are essential to producing seat belt webbing that meets these standards.

By understanding the importance of these safety measures, consumers can appreciate the meticulous efforts that go into making one of the crucial safety features in their vehicles. Whether it's the strength and durability of nylon straps or the stringent testing processes, every aspect of seat belt webbing manufacturing is geared towards ensuring safety on the road.

en

en Español

Español